How We Do It

One of the largest apparel and product decorators in America, we connect you to our manufacturing using modern technology and an emphasis on service.

Our capacity includes 500 embroidery heads, 10 automatic screen print presses, an 80-foot laser bridge, digital heat transfer machines, and direct-to-garment printers. We also have laser etching machines, UV printers, and pad printers, giving us the ability to decorate on a wide range of apparel and products

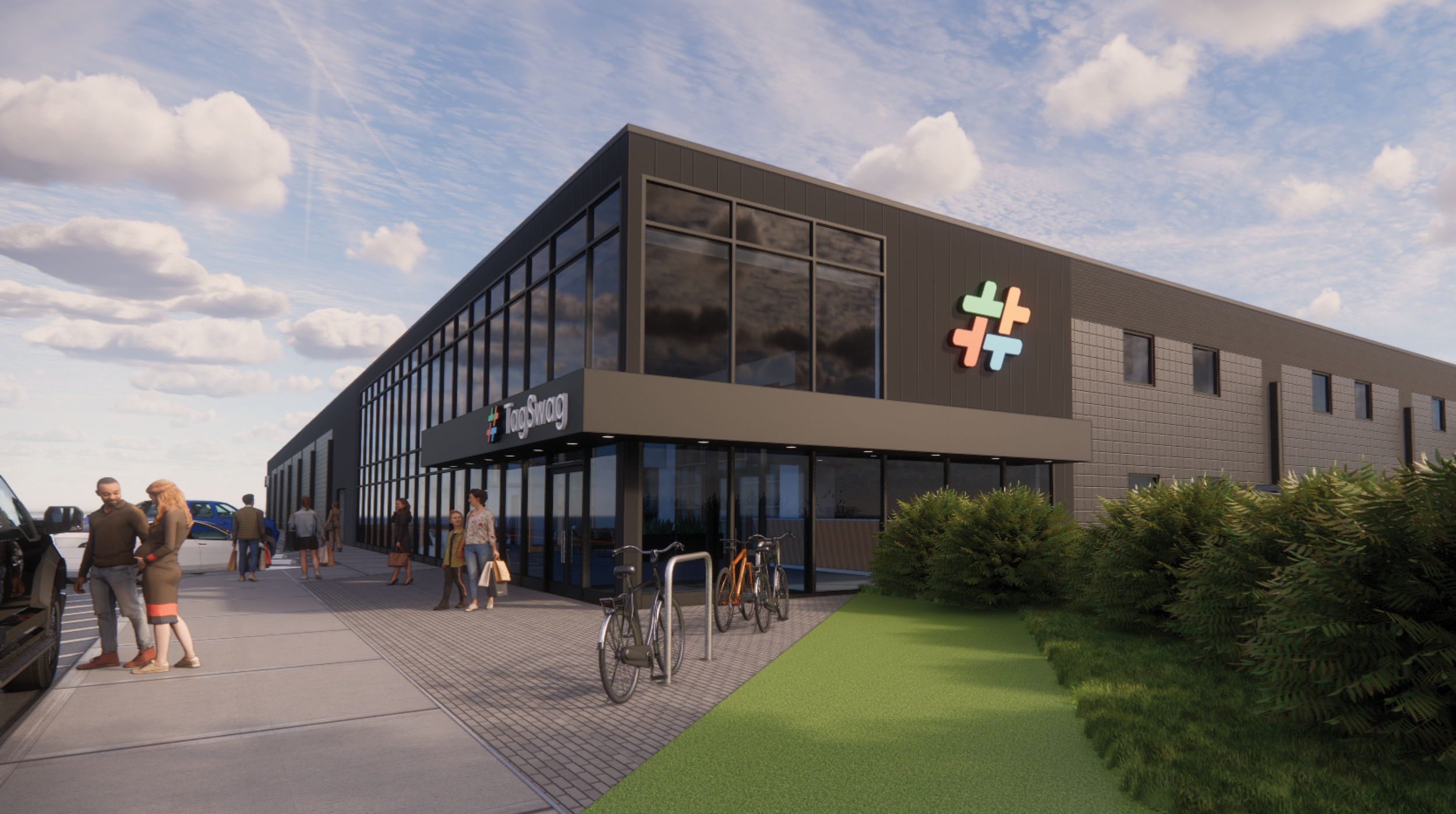

While we’ve been operating out of two 35,000 square ft facilities for the last decade we are excited that in the fall of 2025 we’ll be moving into our dream building in the heart of Louisville. Check out the renderings and follow our progress on social media.

While the offices are cool, not pictured is the best part, the 60k sq ft of manufacturing!

Capacity and Equipment

-

Our capacity includes 500 embroidery heads, 10 screen print presses, an 80-foot laser bridge, digital heat transfer machines, and direct-to-garment printers. We also have laser etching machines, UV printers and pad printers, giving us the ability to decorate on a wide range of apparel and products.

-

✔ 1 — Proel LaserBridge CO2 Applique Cutting Machine

✔ 21 — Barudan Single-Head Machines (15 Needles per Head x21)

✔ 2 — Happy 4-Head Machines (12 Needles Per Head x2)

✔ 6 — Happy 6-head Machines (10 Needles Per Head x1, 12 Needles Per Head x5)

✔ 7 — Happy 12-Head Machines (8 Needles Per Head x7)

✔ 3 — Barudan 12-Head Machines (15 Needles Per Head x3)

✔ 1 — Barudan 15-Head Machine (15 Needles Per Head x1)

✔ 6 — Happy 16-Head Machines (10 Needles Per Head x5, 12 Needles Per Head x1)

✔ 2 — Happy 18-Head Machines (8 Needles Per Head)

✔ 4 — Happy 20 Head Machines (7 Needles Per Head)

Embroidery Size Limits

Left Chest (LC) 3.5" to 4.5" wide

Bags 3.5" wide

Hat Front 2.25" H × 4.5" to 5" W

Visors 1" H × 4" W

Side of Hat 1.5" H or 2.75" W

Back of Hat (Arched) 3.5" wide

Back of Hat (Flex Fit) 4" to 4.5" wide

Sleeve No wider than 3.5"

Mock Cuff 1" high

Cuff (Oxford Sleeve) 1.5" H × 2.5" W

Laser Applique/Full Front Up to 13" wide

Embroidery Notes:

Hats typically sit .5" above the bill

Puff EMB requires additional time and has additional limitations

Metallic thread requires additional time due to stoppages

-

✔ 6 Automatic Screen Print Presses

Capacity: 18,000+ Impressions per shift (roughly 3k impressions, with same logo, per shift) / 6+ Garments printed per press, per minute○ M&R Sportsman 14-Color

○ M&R Sportsman 6-Color

○ M&R Sportsman 10-Color

○ Anatol Volt-M 10-Color

○ Anatol Volt-M 10-Color

○ Anatol Volt-M 14-Color

✔ 2 Manual Screen Print Presses

Capacity: Based on logo size/color count○ Anatol Thunder 8-Color

○ Anatol Thunder 6-Color

✔ Computer to Screen Imaging Technology

Capacity: 200+ Screens Imaged/Exposed per shift○ Exile Spyder II

✔ Custom Pantone Ink Mixing System

Capacity: Based on # of colors in formula/revisions to color to ensure Pantone Matching○ Willflex DM4 Carousel

Screen Print Max Size Limits (in inches)

Adult Full Front/Full Back: 19" H × 15" W

Left/Right Chest: 4" W

On Pocket: 4" W

Left/Right Sleeve: 5.5" W

Youth Full Front/Back: 8" W

Toddler Full Front/Back: 8" W

Limitations

Maximum of 12 colors/screens -

✔ 2 Direct-to-Garment Printers

Capacity: 430+ garments printed per shift○ Brother GTX Pro-B (x2)

○ Shulze Pretreat Cabinet (x2)

-

✔ 2 Direct to Film Printers/Dryers

Capacity: 80,000 SQ. inches of film printed per shift / 800 10"x10" transfers printed per shift○ Coldesi DTF-24H2 printer and sharker/dryer combo (x2)

Placement Max Height and Width

Adult Full Front/Full back 18” H x 14” W

Left/Right Chest 4” W

On Pocket 3” W

Left/Right Sleeve 5.5” W

Youth Full Front/Back 8'“ W

Toddler Full Front/Back 8” W

-

✔ 12 Heat Press Stations

Capacity: 3,600+ transfers applied per shift / 1.5 applications per minute○ Hotronix Dual Air Fusion IQ - 2-Station (x2)

○ Hotronix Auto Claim

○ Hotronix Fusion IQ (x2)

○ MEM Automatic Carousel - 4-Station

○ Hotronix 360 Fusion IQ (Hat Press)

-

✔ 2 Flatbed UV Printers - Capacity: Based on printing method/logo size

○ LogoJet UVx40%

○ LogoJet UVx60

-

✔ 2 CO2 Laser Engravers

Capacity: Based on engraving method/logo size/pass count○ Trotec Laser Speedy 300 (x2)